Recently, a great breakthrough in the research of high-performance special ceramics has been made by Associate Researcher Ji Wei, a member of Academician Fu Zhengyi’s team. The result was published online in Nature Communications(2023, 14, 4889) on August 21 under the title of “Contribution of boundary non-stoichiometry to the lower-temperature plasticity in high-pressure sintered boron carbide”. State Key Laboratory of Advanced Technology for Materials Synthesis and Processing of Wuhan University of Technology was the only communication unit, and the University of Oxford and Hubei Longzhong Laboratory were cooperation units. Associate Researcher Ji Wei and Academician Fu Zhengyi were the co-corresponding authors, and doctoral student Xu Haiyue and Associate Researcher Ji Wei were the co-first authors.

Special ceramics are important support materials for modern industry and high-tech industries due to their excellent properties, such as high strength and high hardness. However, their application scope is still challengedbecause of their intrinsic brittleness with limited plasticity, within the low to moderate temperature range. The improvement of non-oxide ceramic plasticity whilemaintaining the high-temperature strength, is an internationally concerning issue in the academic frontier, which cannot be addressed effectively by the classical strategy.

A new strategy has been put forward by Academician Fu’s team to enhance the plasticity of ceramics by the high-pressure low-temperature(1800°C,80MPa) sintering technology to establish a stoichiometric disequilibrium grain boundary. In this study, boron carbide ceramics is used as an example, where significant non-stoichiometric changes in the grain boundary are induced by high-pressure sintering, decreasing the plastic deformation temperature by 200 °C compared to that of conventionally-sintered specimens. A substantial increase in medium- to low-temperature plasticity is obtained, and extraordinary strength is maintained before the occurrence ofplasticity. This strategy is expected to provide a new approach for high-performance special ceramics to meet application requirements over a wider temperature range.

This work was supported by Prof. Richard Todd’s team from the Department of Materials at the University of Oxford, the David Cockayne Microscopy Center at the University of Oxford, the Micro-nano Structure Research Center in State Key Laboratory of Advanced Technology for Materials Synthesis and Processing (WUT), and the experimental platform of the Shanghai Institute of Silicate Research, Chinese Academy of Sciences. It was also financed by the National Natural Science Foundation of China, the National Key Research and Development Program of China, and the Independent Innovation Fund of Hubei Longzhong Laboratory.

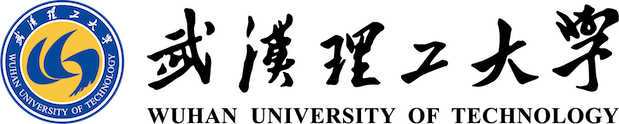

Figure 1: High-pressure sintered boron carbide ceramics have the lower plasticity temperature and maintain high strength before the occurrence ofplasticity

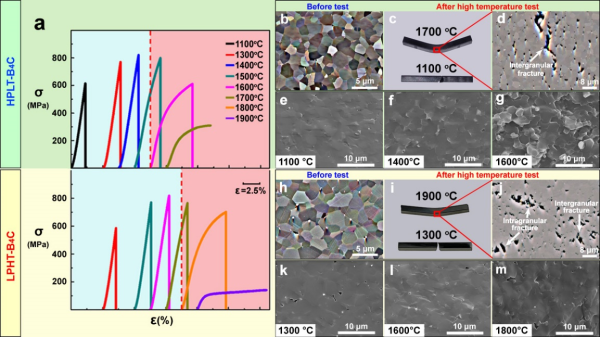

Figure 2: Spherical aberration transmission electron microscopy results show significant non-stoichiometric changes at grain boundaries

Biography:

Fu Zhengyi is the Chief Professor of Materials Science of Wuhan University of Technology, Director of the State Key Laboratory of Advanced Technology for Materials Synthesis and Processing; Academician of the Chinese Academy of Engineering, Foreign Member of the Russian Academy of Engineering, Member of the World Academy of Ceramics, Fellow of the American Ceramic Society, Honorary Fellow of the European Ceramic Society, and Secretary General of the International Federation of Ceramics.

Academician Fu has conducted in-depth research on multifunctional ceramics and ceramic-based composites, structure/function integrated composites, new structures and new material systems, new technologies of in-situ reaction synthesis and preparation, high-efficiency sintering and processing, and biomimetic preparation of material processes. He has been awarded two second prizes for national technological inventions, one third prize for national scientific and technological progress, seven first prizes for provincial and ministerial-level scientific and technological and teaching awards. He has published more than 400 high-level academic papers and has been authorized more than 90 invention patents.

Ji Wei is an Associate Researcher of State Key Laboratory of Advanced Technology for Materials Synthesis and Processing, a member of “Thousand Youth Talents Program for Distinguished Young Scholars” in Hubei province. He studied at the University of Oxford from 2015 to 2016, and graduated from Wuhan University of Technology in 2017 with a Ph.D. degree. He is mainly engaged in the research of high-performance special ceramic materials and has published more than 50 academic papers, been authorized 15 patents, hosted a number of national scientific research projects and won two ministerial and provincial first-class scientific and technological awards, the Ross Coffin Purdy Award of the American Ceramic Society, the Global Young Scientist Award for Engineering Ceramics, and the honor of the top ten scientific and technological advances of young teachers of Wuhan University Technology. He also served as an assistant editor of the national high-quality journal Interdiscip. Mater. and was a member of the young editorial boardof J. Adv. Ceram.

Reviewer: Luo Xiaohan

Rewritten by: Zhou You

Edited by: Li Tiantian, Yu Mengmei

Source: Institute of New Materials (State Key Laboratory of Advanced Technology for Materials Synthesis and Processing)

|

|